We make prototypes even in very small quantities within extremely short time. Already in the sampling phase we apply serial production processes, so that we can verify future serial production. Each order includes an output protocol with feedback from the production process. If a detailed feedback is required, we provide a so-called Build report on manufactured parts with further details of the production process. We procure materials from proven suppliers. Strict requirements on a quality, price and deadlines are applied especially on manufacturers of custom-made parts (PCBs, mechanical parts, cable bundles, etc.) If necessary we are able to combine procured materials.

Production on fully automated machinery

- High quality and accuracy of mounting

- The samples are produced in the same quality as normal serial production

- Easy transfer to serial production

- Recommended for PCBs with higher installation density and larger prototype series (from 10 and more pieces).

Combination of machine and manual production

- Saves your development costs.

- Recommended for development prototypes up to 5 pieces with lower installation density.

- The production of prototypes is close to the quality of standard serial production.

- A laser-burnt printing template is used for applying the alloy and SMD components are manually fitted.

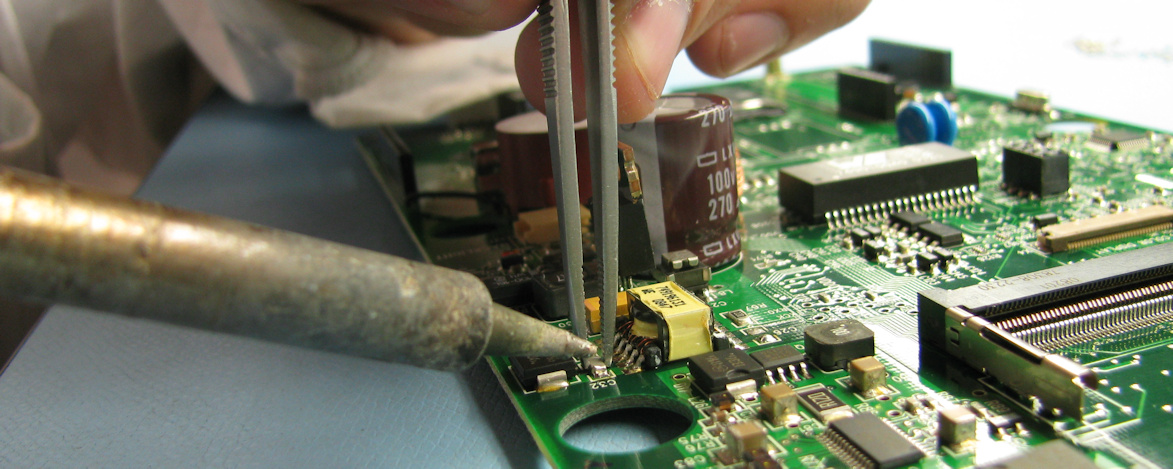

Manual mounting of prototype series

- Reduces your implementation costs to a minimum.

- Recommended for prototype series up to 5 pcs and with lower installation density.

- Manual mounting and soldering of components.